Home > Blog

FEATURED BLOGS →

PCBA Enclosure Design Guidelines

This article discusses some primary considerations impacting PCB enclosure design.

Learn More

Home > Blog

FEATURED BLOGS →

Supply Chain Management in the Electronics Industry

supply chain management, engineering team, test department, design prototype department, executive team, materials management, quality and compliance department

Learn More

Home > Blog

FEATURED BLOGS →

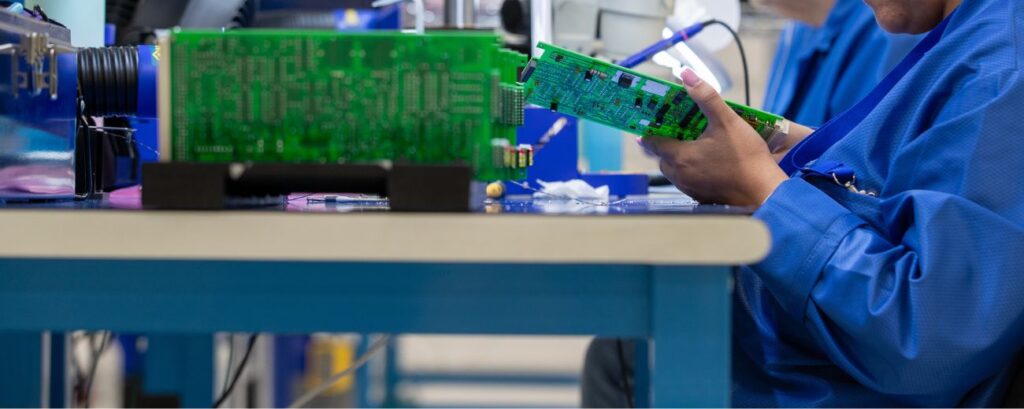

PCBA Reliability Testing: Quality and Efficiency

Electronics are only as valuable as their uptime, as scheduled or (especially) unscheduled maintenance can significantly hamper business operations or end-user satisfaction. However, the nature…

Learn More

Home > Blog

FEATURED BLOGS →

PCB Test Point Guide for Successful Design

PCBs require test points to be strategically designed into the board, along with components and routing the connections. Bare board continuity testing, in-circuit testing,…

Learn MoreOur Blog

Blog

Navigating And Managing PCB Production Costs in 2025

8 Min. To Read

The landscape of PCB manufacturing is shifting, and designers need to adapt their supply and manufacturing chains to stay competitive....

Blog

Semiconductor Industry Forecast 2025

14 Min. To Read

The 2025 semiconductor market outlook with segment forecasts, regional analysis, and emerging technology trends shaping industry growth.

Blog

PCB Assembly BOM Best Practices for Low-Volume Builds

9 Min. To Read

Here are some of the best practices for your PCB assembly BOM to help streamline component management and optimize your...

Blog

IPC Class 2 PCB Requirements

9 Min. To Read

The Global Electronics Association, formally known as IPC, publishes the industry standard for PCB manufacturing, IPC-A-610. IPC-A-610 outlines IPC class...

Blog

US Manufacturing Onshoring: What to Know

5 Min. To Read

This piece discusses the advantages of switching to US-based PCB manufacturing.

Blog

Creepage and Clearance Standards for High-Voltage PCBs

8 Min. To Read

If a high voltage develops between exposed metal on a PCB, electrostatic discharge can occur if the charge exceeds the...

Search