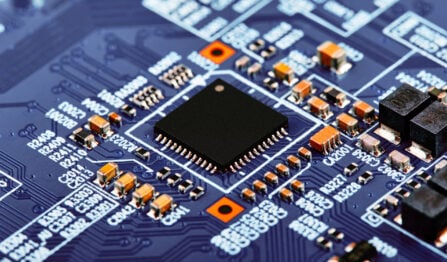

There are a lot of important aspects of building a low-volume product, and managing costs—both in terms of time and money—is often pretty high on the list. However, when it comes to low-volume PCB assemblies, the focus is often more on the functionality of the PCB instead of choosing the best parts and materials. In these projects, it is essential to remember that without proper management, the bill of materials (BOM) can quickly get out of control, costing you time and money.

The good news is that with some added care on your part and by working with a contract manufacturer who specializes in providing high-quality, low-volume builds, you can have the best of both worlds—functional circuit boards and an accurate BOM that helps streamline your project costs. The key is to design your board and manage your components correctly so that your contract manufacturer can build the boards you need without any problems. Here, then, are some of the best practices that you can put into place for your PCB assembly BOMs.

Best Practices When Creating Your PCB Assembly BOM

Generating a bill of materials (BOM) report of your printed circuit board is a fairly simple task with most PCB design CAD tools. Usually, it is just a matter of selecting the report type and format you want from a menu of different reporting options.

The critical part of PCB BOM creation is designing the schematic and choosing the correct parts that the BOM report generator will use to pull its information from. For an accurate BOM, you will want to make sure the components you are using are functionally correct, available, and at the best price.

There are also some other details you should consider for your BOM as well. Some of these may not be included in the information that is listed in the schematic components, and it may take some additional work from you to include them. Here are some of those details to keep in mind:

- Component manufacturer: Your CM should work with many different component manufacturers, which will allow them to source parts at a better price and lead time than what is available to you. However, if you need a specific component manufacturer due to the electrical performance of any of your parts, it is a good practice to note that on your BOM. This will ensure that your CM will understand immediately what your needs are for that part.

- NRND, EOL, or OBS components: It is helpful to alert your CM if you are purposely using parts that are not recommended for new designs (NRND), have gone end-of-life (EOL), or are obsolete (OBS). Usually, your CM will recommend substitutions for readily available parts, so be sure to clarify your needs.

- Verify the part descriptions with the part numbers: Sometimes, parts can be updated in the design without their part numbers being updated. Also, it is not unheard of for the CAD library part to have incorrect information that is passed on to the BOM. It is a good practice to confirm your parts in the final BOM to make sure your CM orders the parts you are expecting.

- Inspect the BOM for format: CAD tools have many options when it comes to generating a BOM report, and it isn’t unusual to see certain classes of parts omitted, reference designators left off, or the BOM sorting on the wrong data field. Always check to make sure that you are sending out a BOM that is formatted the way the CM needs it to be.

- Validate quantities & reference designators to package types: Make sure that all of your parts are represented accurately. Sometimes, a designer will inadvertently renumber a reference designator to the wrong prefix, like using an “R” for a capacitor, or a socket gets replaced with an IC without the socket reference being updated accordingly.

Paying attention to BOM details like this can save you costly assembly problems if they are dealt with before the board goes to manufacturing.

Knowing what your CM needs on your PCB assembly BOM for low-volume builds helps prevent problems and delays.

Assembly Difficulties Due to BOM Problems

When the above details are not accounted for, there can be a host of problems with the bill of materials for the printed circuit board. These problems can cause assembly delays or affect the performance of the assembled PCB. Some of the problems that might happen include:

- Schedule delays due to waiting for components from a specific manufacturer when any equivalent would have worked.

- Functional problems occurred because a certain manufacturer’s part was not specified, and the substitute part did not have the same performance characteristics as the part that was used during prototyping.

- Performance problems due to questionable or outdated NRND, EOL, or OBS components that had to be purchased from non-approved sources.

- Incorrect part numbers or descriptions can result in the wrong part being installed during assembly.

- The component does not assemble correctly to the PCB land pattern because the design specified an incorrect footprint shape for it.

Problems like these can be traced back to issues with the BOM, and they can cost you time and money. The best thing you can do is to make sure that your design and BOM information are correct before you commit to manufacturing. The good news is that you have a partner in this process who has a vested interest in helping you to create a good bill of materials information.

Delay Impacts of Common BOM Issues

By catching issues early in the CAD tool or BOM “scrub” stage, you can save hundreds to thousands of dollars per project and shave days or weeks off your production schedule.

| Phase Discovered | Issue | Approx. Delay Impact |

|---|---|---|

| Design | Missing/incorrect component manufacturer call-out | 0–1 day |

| Using NRND/EOL/OBS parts without flagging | 0–2 days | |

| Footprint mismatch (wrong land pattern) | 1–2 days | |

| Assembly | Wrong part number/description in BOM | 3–5 days |

| Substitute the part with poor performance | 1–2 weeks | |

| Long lead-time part ordered late | 1–3 weeks |

Notes on impact estimates:

- Catching these issues in the design/BOM scrub phase saves the most time and money, which can range from hundreds to thousands of dollars and days to weeks of schedule.

Partnering with VSE for PCB Assembly BOM Best Practices & End-to-End Services

Leverage PCB Assembly BOM Best Practices throughout your project lifecycle with VSE’s comprehensive service portfolio, each designed to catch BOM issues early and keep your builds on time and on budget:

- Comprehensive PCB Assembly & Testing

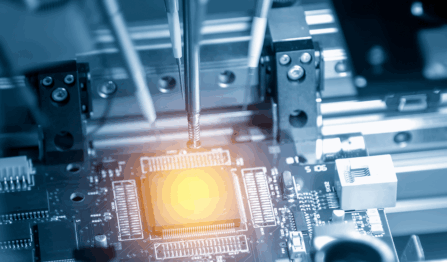

Industry-leading assembly of prototypes, NPIs, and high-volume lots, paired with full testing (AOI, ICT, FCT, environmental) to validate every BOM entry before shipment.

➔ Learn more: PCB Testing Services - PCB Engineering Services

From schematic capture and library development to DFM reviews, signal-integrity analysis, and rigid-flex design, our engineers embed BOM best practices at the source.

➔ Learn more: PCBA Engineering Services - Rapid Prototyping

Bridge proof-of-concept to production with quick-turn prototypes (10–100 boards) that include DFM checks and BOM scrubs, preventing downstream surprises.

➔ Learn more: PCBA Prototype Service - Quick-Turn PCB Assembly

Turnkey SMT/TH assembly in 24–72 hours, complete with BOM validation, component sourcing, and expedited options to keep your time-to-market on track.

➔ Learn more: Turnkey PCB Assembly - Box-Build Assembly: Full electromechanical integration, enclosures, wire harnesses, panel builds, and final system-level testing—to ensure every BOM detail aligns with the finished product.

➔ Learn more: Box-Build Assembly

Top Industry Verticals for Low-Volume Expertise

VSE’s low-volume expertise spans a variety of demanding markets. Here are a few where our deep domain knowledge makes the biggest impact:

- Aerospace & Defense: Mission-critical PCBs with zero-fail requirements, strict traceability, and MIL-STD compliance.

- Medical Devices: ISO-13485 certified processes, biocompatible materials, and rapid prototyping for regulatory submissions.

- Industrial Automation & Controls: Robust designs for harsh environments, small batch builds for pilot production, and lab testing.

- Telecommunications & Networking: High-speed, impedance-controlled boards for 5G, data-center interconnects, and fiber-optics modules.

- Automotive & Transportation: Build-in-vehicle prototypes, EMC/EMI testing support, and component lifecycle management for multi-year programs.

How VSE Applies PCB Assembly Best Practices in Top Industry Verticals

| Industry Vertical | Key Requirements | How VSE Applies PCB Assembly BOM Best Practices |

|---|---|---|

| Aerospace & Defense | MIL-STD traceability, zero-fail reliability | Rigorous BOM scrub for approved manufacturers, NRND/EOL alerts, full documentation control to meet MIL-STD compliance. |

| Medical Devices | ISO-13485 quality, biocompatibility, rapid design iterations | BOM validation against medical-grade components, footprint checks, and lifecycle monitoring to ensure regulatory readiness. |

| Industrial Automation & Controls | Harsh-environment robustness, small pilot batch flexibility | DFM reviews with a focus on high-temperature and vibration-rated parts, and BOM reviews to optimize sourcing for low-volume runs. |

| Telecommunications & Networking | Impedance control, high-speed signal integrity | Component-level BOM checks for matched impedance parts and qualified vendors. |

| Automotive & Transportation | EMC/EMI compliance, long-term availability | BOM governance to enforce OEM-approved part lists, lifecycle alerts for EOL/OBS components, and consignment stocking to prevent disruptions. |

How to be Assured of a Complete and Accurate BOM

Accurate PCB assembly BOM information is just as important to your contract manufacturer as it is to you. They want their assembly lines to run smoothly, and they want your board build to be successful. Because of this, your CM will usually work with you to ensure that the BOM for your PCB is the best that it can be.

At VSE, we do a full BOM analysis and “scrub” of all BOMs on incoming projects with the following goals in mind:

- Identify long lead times and inventory issues.

- Identify NRND, EOL, and OBS issues.

- Identify lower-cost alternatives for expensive components.

- Validate part numbers with their descriptions.

If any of these problems are discovered in our analysis, we will make recommendations to you for corrective actions. We will also continue to monitor the status of your project’s components during the life of the build so we have advanced warning of any potential changes to their availability. We can do this because of the relationships that we have built up over the years with reputable component brokers. Once completed, we will generate a final “clean” BOM for your project so that your documentation is completely up to date and in sync with your design data.

If you are looking for a CM that prides itself on its care and attention to detail to ensure that each PCB assembly is built to the highest standards, look no further than VSE. Contact us today to learn more about partnering with us for your next project.