Creepage and clearance prevent ESD between conductors on a high-voltage circuit board.

Any PCB carries essential industry standards that should be followed and considered during design and assembly. Among the various PCB design standards, one crucial set governs creepage and clearance distances between neighboring conductors on a PCB. These standards aid in designing electrostatically safe products, especially those running at high voltage.

If a high voltage develops between exposed metal in a PCB, electrostatic discharge can occur if the charge exceeds the threshold for dielectric breakdown; this material failure damages components and, in extreme cases, causes board conflagration. Creepage and clearance limits between exposed metal on your PCB have codifications in critical industry standards for observation during design and manufacturing. These standards are industry-agnostic, but different standards are broadly application-specific.

When a CM produces a run of PCBs, their goal is to comply with standards on creepage and clearance; CMs confirm these distances in your design data to ensure adherence during DFM checks. By eye, it’s difficult to determine creepage and clearance distances between traces and components on a PCB, but various PCB design tools help prevent violations with design rule checklists. Ultimately, creepage and clearance limits also change when considering environmental factors, substrate material, DC or peak AC voltage, and component arrangement.

Creepage and Clearance Comparison

| Creepage | Clearance |

|

|

Creepage and Clearance on a PCB

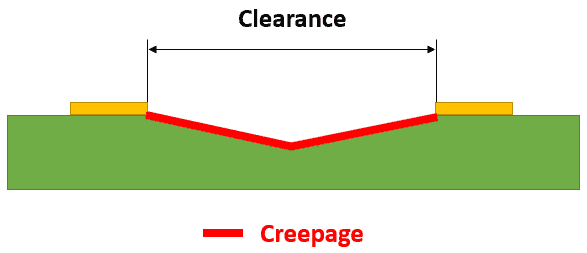

These two terms are closely related and refer to two ways to measure the distance between conductive elements on the surface of a PCB. Note that creepage and clearance have nothing to do with trace width during routing.

There are two ways to measure the distance between two conductors on a board:

- Creepage is the distance along the board’s surface.

- Clearance is the distance in air between two conductors (AKA air gap).

If this needs additional clarification, take a look at the diagram below. This image shows a side view of a PCB with a valley between two copper conductors. Creepage is shown in red and follows the surface of the board.

Visual comparing creepage and clearance distance.

The diagram above suggests that the creepage distance is always larger than the clearance distance, but this is not always true. Once you factor in components with hanging conductive elements/heat sinks, creepage and clearance distances become less distinguishable. Consider the case below, where two decawatt (DPAK) package components have heat sinks hanging over the pads. In this case, the clearance distance uses the overhanging metal edge of the DPAK components.

Creepage and clearance between two DPAK ICs and their mounting pads (side view)

When laying out components, considering orientation, spacing, and the presence of any overhanging conductors to ensure observation of creepage or clearance limits is a necessity. In some cases, simply rearranging or shifting components will place enough clearance between exposed metal so that you can comply with safety standards. In other instances where creepage rule violations occur while clearance is satisfied, one option is to place a notch that passes through the entire circuit board between components. A knowledgeable CM can recommend the best design changes for your board during a DFM check.

Important Creepage and Clearance Standards

Several important standards define clearance and creepage distances in a PCB. The best-known standards are IPC-2221, IPC-9592B, UL-61010-1, and UL-60950-1 (second edition). These standards list different creepage and clearance design rules for products in various applications and operating environments. While reproducing every rule in these standards is beyond the scope of this article, designers should consult the creepage and clearance limits relevant to their application.

IPC-2221 and IPC-9592B

IPC2221A is a more general standard that specifies creepage and clearance distances. However, the creepage and clearance rules subdivide into different application areas. The limits described in IPC2221 differ by DC or peak AC voltage level, substrate material, etc. Limits for internal and coated or uncoated conductors on external layers are also of consideration. IPC-9592B is more specific in that it defines trace clearance and creepage requirements in power conversion devices running above 100 V.

UL-61010-1

This set of standards specifies safety and design requirements for electrical testing equipment, laboratory equipment, and industrial process control equipment. This standard excludes several products in different application areas. You can find a complete list of excluded application areas and the relevant UL standards in Section 1.1.2 of the UL-61010-1 standards.

UL-60950-1

This particular standard largely replicates the IEC-60950-1 standard for information technology products. This standard specifies high- and low-voltage equipment safety standards, including creepage and clearance distances on a PCB. This standard is broad enough to cover everything from office to telecommunications equipment.

The Value of a Knowledgeable Partner

Given the list of rules related to PCB creepage and clearance and the complexity they can place on DFM checks, it helps to work with a CM with deep knowledge and experience of different design and quality standards. Your CM can be a major asset in ensuring high yield, quality, and safe operation of your new product.