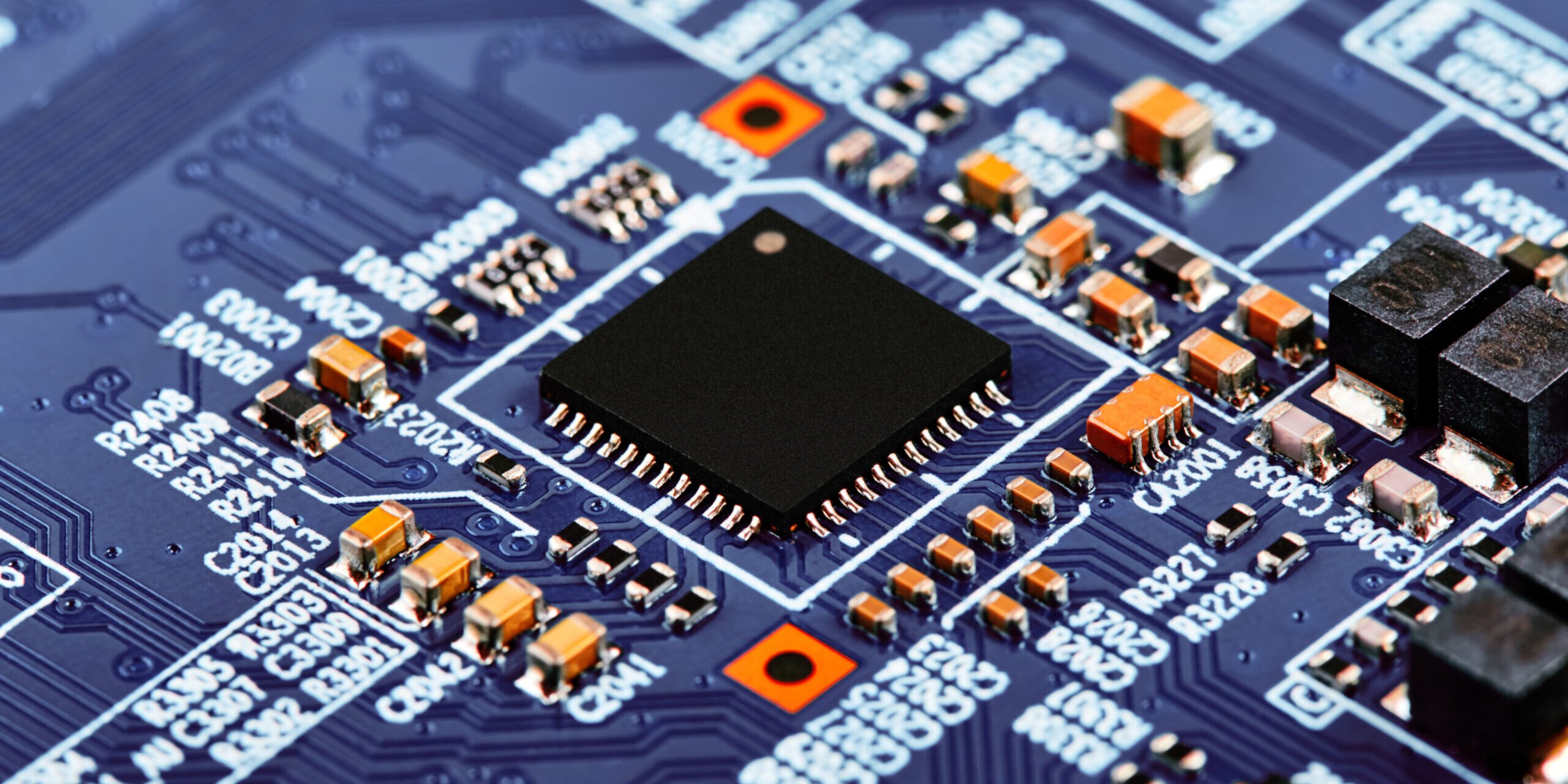

At VSE, reliability begins at the design stage. As a trusted U.S.-based electronics manufacturing partner, VSE applies Design for Manufacturability (DFM) and Design for Assembly (DFA) principles throughout its printed circuit board assembly (PCBA) production process to ensure every board is built with precision, consistency, and quality.

In today’s competitive electronics landscape, integrating DFM and DFA early in the design phase is crucial to prevent costly revisions, minimize production errors, and expedite time to market. By addressing both manufacturability and assembly requirements from the outset, VSE enables innovators to bring high-performance, life-changing technologies to market faster and with greater confidence.

This article explores how VSE’s engineering team applies DFM and DFA best practices across every stage—from design through to PCB assembly—to enhance reliability and streamline production.

Understanding Design For Manufacturability (DFM)

DFM is the process of designing PCBAs with manufacturing in mind, reducing potential errors before they reach production. Once considered a downstream concern, DFM is now a core element step early in the design cycle. As technologies advance and time-to-market windows become increasingly tight, taking ownership of DFM before layout ensures greater efficiency, consistency, and reliability.

At VSE, DFM reviews are more than a checkpoint—they’re an essential collaboration between engineers and manufacturers. Each design undergoes a comprehensive evaluation to identify potential challenges and implement improvements before production begins.

During a DFM review, VSE’s engineering team examines:

- Component Selection And Availability: VSE recommends cost-effective, in-stock alternatives to prevent delays caused by unavailable or high-cost materials.

- Fabrication Readiness: Potential design errors that could complicate fabrication are identified early and corrected, ensuring a smooth board production process.

- Placement Optimization: Components are repositioned for automated assembly and efficient soldering, improving throughput and reducing rework.

- Testing Strategy: VSE helps implement comprehensive, methodical test plans to catch issues early and eliminate the risk of defective boards reaching end-users.

- Human Interface And Rework Accessibility: Designs are refined for technician-friendly layouts that simplify inspection, testing, and maintenance.

By addressing these considerations upfront, VSE prevents costly redesigns, avoids production stoppages, and ensures every board is built for both performance and manufacturability. The result is a faster and more reliable path from concept to a market-ready product.

Layout Analysis For Improved Manufacturing Yield

Even the most advanced PCBA designs can face challenges when moving from concept to production. Differences between what designers envision and what manufacturers can physically produce often lead to costly revisions or lower yields. At VSE, this gap is eliminated through a meticulous layout analysis process that aligns design intent with real-world manufacturability.

VSE’s engineering team uses advanced Electronic Computer-Aided Design (ECAD) verification tools to review and validate every layer of a board before fabrication begins. This ensures that each element, from hole tolerances to silkscreen alignment, meets both design and manufacturing requirements, reducing the risk of defects and rework.

Key areas of focus during VSE’s layout analysis include:

| Board Layout Analysis to Improve Yield | |

| Plated holes and pads | Engineers verify hole-to-pad ratios and annular ring compliance to maintain electrical integrity and prevent plating defects. |

| Non-plated holes | Each hole’s size and placement are confirmed against fabrication artwork for precise mechanical fit and alignment. |

| Signal layers | Trace widths and spacing are analyzed to confirm impedance targets, ensuring signal accuracy and board performance. |

| Acid traps | VSE identifies and corrects trace angles that could trap etchant material, preventing corrosion or future circuit failure. |

| General tolerance | All dimensional allowances are reviewed to guarantee that the board maintains mechanical stability during production. |

| Silkscreen and solder mask | Teams verify mask clearances and silkscreen spacing to meet IPC standards and eliminate clipping or misalignment issues. |

This rigorous process transforms potential production risks into opportunities for optimization and improvement. By addressing manufacturability during layout, VSE enhances yields, shortens lead times, and ensures every PCBA moves through production smoothly and predictably.

At VSE, layout analysis isn’t just about checking boxes—it’s about engineering reliability into every layer of the board, shortening lead times, and ensuring clients receive products that meet the highest standards of quality and performance.

Key Principles Behind Effective DFM

Effective DFM is the foundation of every reliable PCB assembly. It begins at the concept stage and continues through every design iteration, ensuring each product is built for both performance and production efficiency. The following principles guide how VSE’s engineering team applies DFM to enhance yield, ensure compliance, and accelerate delivery.

Early DFM Integration

Integrating DFM early in the design cycle is one of the most powerful ways to ensure project success. VSE’s engineers collaborate with clients during the initial layout phase to identify and resolve potential challenges before they affect production.

Early design reviews allow adjustments to component placement, material selection, and stackup configuration while changes are still cost-effective. This proactive approach minimizes redesigns, shortens lead times, and ensures every board is manufacturable from day one.

DFT, Assembly, Logistics, Standards & Cost

A truly effective DFM strategy must work in harmony with design for testability (DFT), assembly requirements, logistical planning, and cost management. VSE evaluates each project across these interconnected factors to achieve a balance between technical performance and commercial viability.

- DFT: Engineers design test points and access features to simplify quality verification throughout production.

- Assembly: Layouts are optimized for automated placement, soldering, and inspection to improve throughput.

- Logistics: Early coordination with supply chain teams ensures components are available, authentic, and traceable.

- Standards: Every process follows IPC-610 and ISO-9001/13485 quality requirements.

- Cost: VSE prioritizes efficiency, sourcing value-driven materials without compromising quality or reliability.

This holistic perspective enables clients to move seamlessly from prototype to production with predictable outcomes.

Rule-Based Layout & Physical Design Considerations

VSE’s engineering team enforces strict rule-based layout standards to maintain manufacturing precision. Design rules define acceptable limits for trace width, pad spacing, via aspect ratios, and copper balance, ensuring each layer meets IPC and customer specifications.

Physical design elements, such as hole size ratios, solder mask clearances, and thermal relief placement, are also reviewed to prevent warping, shorts, or uneven heating. By applying these standards consistently, VSE ensures that boards perform reliably in even the most demanding environments.

Prototype & Iteration With DFM Checks

Prototyping is an essential validation step in the DFM process. Each prototype produced by VSE undergoes a comprehensive DFM review before and after assembly. Engineers use the results to refine design data, confirm manufacturability, and guide future iterations. This iterative cycle ensures that by the time a design reaches volume production, it already meets all performance, quality, and efficiency targets.

Preventing Common Manufacturing Defects

Manufacturing issues often stem from small design oversights. VSE’s DFM evaluations are designed to eliminate these risks before production begins. The team reviews component spacing, copper distribution, and solder mask alignment to prevent shorts, voids, or incomplete connections.

Thermal balance and pad geometry are verified to prevent defects such as tombstoning or cold solder joints. Each preventive measure ensures that the final assembly meets both electrical and mechanical reliability standards.

Documentation, Standards & Communication

Accurate documentation and clear communication are essential to the successful execution of DFM. VSE maintains detailed manufacturing files, revision histories, and test data for complete traceability.

Throughout the process, design and production teams maintain open communication channels to address questions promptly and keep all stakeholders informed. This disciplined documentation and collaboration ensure compliance, accountability, and repeatable quality across every project.

The DFM Guidelines Checklist

VSE’s engineering team relies on a detailed DFM checklist to ensure every PCBA design is ready for efficient, high-quality production. Each review confirms that design details align with manufacturing capabilities, reducing the likelihood of delays, costly revisions, or assembly errors. Key areas reviewed during DFM evaluation include:

- Holes: Verification of drill locations, edge spacing, and design consistency to maintain structural integrity.

- Components: Ensuring proper assembly spacing, alignment for wave soldering, and adequate test access.

- Traces: Checking spacing to prevent solder shorts, confirming edge clearances, and managing thermal balance.

- Planes: Inspecting thermal pads, validating keepout areas, and removing isolated copper that could cause shorts.

- Solder Mask: Confirming clearance accuracy and full mask coverage between pads to prevent bridging.

- Silkscreen: Ensuring text and markings are correctly positioned without overlapping holes, pads, or components.

Each checkpoint supports VSE’s goal of optimizing manufacturability while preserving electrical performance and long-term reliability.

Resolving Common PCBA Errors with the VSE Checklist

Balancing electrical performance with manufacturability can be challenging for PCBA designers. High-density layouts often push design limits, and what works in theory may not translate smoothly to production. VSE’s DFM checklist bridges this gap by identifying and resolving conflicts early in the process, ensuring each board meets both performance and manufacturing requirements.

VSE engineers review every design detail to catch the most common DFM issues before they reach fabrication, including:

- Component Placement: Close or misaligned components can interfere with the soldering and assembly process. VSE adjusts spacing and orientation to support efficient, defect-free production.

- Pad Sizing: Incorrect pad dimensions cause uneven heating and tombstoning on small components. VSE verifies pad geometry to ensure consistent solder flow and reliable joints.

- Clearance: Minimal spacing near components or board edges complicates assembly and rework. VSE enforces proper clearances to maintain smooth soldering and inspection.

- Copper and solder mask slivers: Detached copper or mask fragments can create shorts or expose traces. VSE identifies and removes these risks to ensure long-term board reliability.

By addressing these issues proactively, VSE turns potential design weaknesses into opportunities for optimization. Each checklist-driven review enhances product quality, minimizes rework, and ensures that every PCBA transitions smoothly from design to dependable production.

VSE’s DFM Approach In PCBA Manufacturing

Building high-performance electronics requires foresight. VSE’s DFM-driven workflow embeds manufacturability into every stage of PCBA design and production, ensuring that reliability, cost efficiency, and performance are never competing priorities.

Instead of treating DFM as a late-stage verification step, VSE engineers apply it from the earliest design discussions, evaluating layout feasibility, material selection, and assembly complexity before production begins.

This proactive, integrated approach reduces redesigns, accelerates delivery time, and ensures consistent quality across every build. By identifying potential challenges early, such as improper trace dimensions, complex assembly geometries, or unavailable components, VSE helps clients avoid costly rework and rejected builds.

Pre-schematic

VSE’s engineers assess the project at the pre-schematic stage to ensure that design intent aligns with manufacturability. Early coordination between engineering, procurement, and production allows the team to make informed component choices that balance cost, availability, and performance.

Every selection matters. Factors such as lead pitch, package type, size, and thermal characteristics directly affect how efficiently a board can be assembled. Opting for a lower-cost part may save money upfront, but it can introduce complications, such as mixed assembly requirements or longer lead times.

VSE’s pre-schematic reviews prioritize long-term efficiency over short-term cost. Engineers select components that simplify automated assembly, maintain material consistency, and minimize the need for later redesigns. This foresight ensures production schedules remain predictable, even when supply chain conditions shift.

By setting clear manufacturing parameters early, VSE establishes a strong foundation for reliable, repeatable, and scalable PCBA production that meets performance, compliance, and delivery goals.

Stackup

A PCBA’s performance and durability depend heavily on how its layers are constructed. In VSE’s DFM process, the stackup design is one of the first areas analyzed to ensure structural integrity, electrical performance, and manufacturability align.

Each stackup consists of alternating layers of copper and substrate material, typically a fiberglass weave reinforced with epoxy resin that cures and hardens during the lamination process. VSE engineers evaluate this vertical construction to confirm it meets the required board thickness and supports the intended signal and power plane architecture.

During this stage, impedance control is a key focus. VSE reviews trace geometries, such as microetched, stripline, and single- or differential-ended traces, to ensure each maintains proper impedance across all layers. Copper thickness, both in the base foil and after plating, is also verified. Excessive etching or uneven copper distribution can lead to under-etched features that weaken the board mechanically or cause signal loss.

By optimizing the stackup early, VSE ensures balanced performance, precise impedance, and strong layer adhesion, resulting in PCBs that meet the highest standards of reliability and electrical consistency.

Design Rules

Effective PCBA manufacturing starts with well-defined design parameters. In VSE’s DFM approach, design rules act as a shared framework between engineering and production, establishing the limits that ensure each board can be built accurately, efficiently, and at scale.

VSE engineers set and verify these rules early in the design process to maintain alignment between electrical performance and manufacturability. They cover critical factors such as trace width, spacing, copper balance, and via construction, all of which influence yield and long-term reliability.

One key consideration is the via aspect ratio, which defines the relationship between board thickness and hole diameter. To maintain complete plating coverage and prevent defects, VSE ensures this ratio remains within proven process limits—typically not exceeding 10:1 for mechanically drilled vias. Exceeding this range can result in incomplete plating and potential electrical failure.

VSE’s DFM reviews also check for even copper distribution and balanced layer design to avoid warping or uneven etching. By enforcing these standards, VSE helps designers avoid common pitfalls and ensures each PCB maintains consistent impedance, mechanical strength, and electrical precision throughout production.

This disciplined, rule-based approach enables VSE to deliver high-yield, repeatable manufacturing outcomes that meet the rigorous demands of advanced electronics.

Electrical Testing

Electrical testing plays a crucial role in verifying that each board performs as intended. These evaluations confirm the integrity of every circuit, detect potential defects early, and ensure manufacturing consistency across production runs.

Throughout fabrication and assembly, VSE employs multiple forms of testing to validate outcomes and minimize yield losses. In-circuit testing (ICT) verifies continuity, checks for open or short circuits, and evaluates key electrical properties—such as capacitance—by comparing the results directly against the design’s reference data. For boards with fine-pitch components or lower production volumes, a flying probe test may be used instead, providing precise validation without the need for custom fixtures.

When working with high-density interconnect (HDI) designs, VSE applies the same rigorous testing standards while accounting for the additional complexity of these advanced assemblies. HDI boards often use blind or buried microvias to achieve compact layouts, requiring sequential drilling and lamination steps. VSE’s DFM reviews help balance these design choices by weighing performance and space requirements against cost, yield, and manufacturability, ensuring that HDI designs remain both high-performing and practical to produce.

Through this structured testing framework, VSE verifies every connection, layer, and circuit characteristic before boards move to final assembly. The result is a reliable, production-ready product that meets exacting electrical and performance standards.

Integrating DFM And DFA Standards For High-Quality Outcomes

Even the best manufacturing plan can fall short if assembly complexity isn’t addressed early. DFM minimizes production errors, while DFA streamlines the assembly process by reducing part counts, enhancing workflow, and shortening production cycles. When combined, they create a unified Design for Manufacturing and Assembly (DfMA) framework that drives efficiency and quality across every stage of production.

VSE integrates DfMA principles early in the design process to ensure compliance, repeatability, and assembly flow. The company’s engineers evaluate each board for manufacturability, assembly flow, and human interface to ensure that every design can move seamlessly from prototype to production.

Key considerations in VSE’s DfMA evaluations include:

- Reducing Unnecessary Components And Circuitry: Simplifying layouts to lower assembly complexity and improve throughput.

- Standardizing Parts: Replacing unique or hard-to-source components with proven, industry-standard alternatives to enhance sourcing stability.

- Optimizing For Accessibility And Rework: Positioning connectors, test points, and components for easy assembly, inspection, and long-term maintenance.

To achieve these outcomes, VSE conducts comprehensive DfMA reviews throughout the design cycle, not after. These reviews translate design priorities into practical actions, keeping manufacturability, assembly efficiency, and product performance aligned at every step.

The process includes:

- Performing Detailed Design Assessments: During DfMA reviews, engineers analyze component placement, solder accessibility, and assembly flow to identify potential challenges before fabrication.

- Involving Multidisciplinary Expertise: Mechanical engineers, PCBA designers, and library specialists collaborate to validate spacing, orientation, and part alignment for smooth assembly.

- Leveraging Advanced 3D CAD Validation: Using ECAD tools with 3D modeling, VSE simulates mechanical fit, detects interference with enclosures or other boards, and confirms clearances.

- Collaborating Closely With Manufacturing Partners: VSE maintains direct communication between design and production teams to align intent, quality standards, and execution.

By combining DFM and DFA standards within a single, proactive workflow, VSE delivers PCB assemblies that are efficient to produce, consistent in quality, and optimized for long-term reliability—ensuring every product is built right the first time.

Why Businesses Trust VSE As Their PCBA Manufacturing Partner

For more than forty years, VSE has been a trusted name in U.S.-based electronics manufacturing, recognized for its precision, dependability, and partnership-first approach. The company’s reputation has been built on consistent quality, advanced engineering expertise, and a steadfast commitment to helping innovators bring life-changing and life-saving technologies to market with speed and confidence.

VSE’s manufacturing strength lies in its vertically integrated quality assurance and quality control (QA/QC) systems, designed to ensure flawless performance across every build. Each printed circuit board assembly undergoes extensive testing, including in-circuit, functional, environmental, HIPOT, and X-ray evaluations.

Beyond testing, VSE maintains strict adherence to IPC/WHMA-A-620 standards, ISO 9001 and ISO 13485 certifications, and a comprehensive manufacturing system (MS) that provides full traceability and compliance throughout production. Every phase, from prototype validation to final inspection, reflects the company’s unwavering focus on precision, consistency, and reliability.

By combining its DFM-first methodology with this deep-rooted culture of quality, VSE helps clients achieve measurable benefits that directly impact production and performance: faster project turnaround, optimized efficiency, and enduring reliability. Industries that partner with VSE gain the advantage of:

- Faster time to market through early manufacturability validation and rapid prototyping that reduces design-to-production cycles.

- Lower costs and higher efficiency, achieved through optimized layouts, minimized rework, and intelligent use of automated processes.

- Superior quality and reliability, maintained through extensive testing, traceability, and continuous process improvement.

- Smooth scaling and supply chain integration supported by vertically integrated operations and robust domestic sourcing networks.

- Collaborative partnership and risk reduction, enabled by transparent communication and engineer-to-engineer coordination at every stage.

Through these strengths, VSE continues to be the electronics manufacturing partner of choice for organizations across medical, aerospace, defense, and communications sectors—delivering trusted solutions that consistently perform to the highest standards.

Your Reliable PCBA Production Partner For Quality & Speed

VSE delivers more than precision manufacturing—it provides a partnership built on collaboration, quality, and trust. Every project reflects the company’s pillars of engineering expertise, agile production, uncompromised quality standards, and transparent supply chain management, ensuring each board performs reliably in the field.

By integrating a DFM-first mindset with hands-on communication and rigorous process control, VSE empowers innovators to bring advanced technologies to market faster and with greater confidence. For businesses that demand excellence at every stage of production, VSE remains the reliable U.S.-based manufacturing partner of choice.

Searching for a trusted PCBA partner? See how VSE’s PCBA design process ensures quality and reliability.