Sourcing electronic components has become increasingly complex as global supply chains face disruptions, shortages, and the growing threat of counterfeit parts. These challenges can lead to production delays, quality issues, and missed market opportunities, directly impacting business performance and customer trust.

VSE helps eliminate these risks with proven procurement expertise, validated suppliers, and a transparent compliance framework. Our team navigates component shortages, verifies part authenticity, and manages supplier logistics on your behalf.

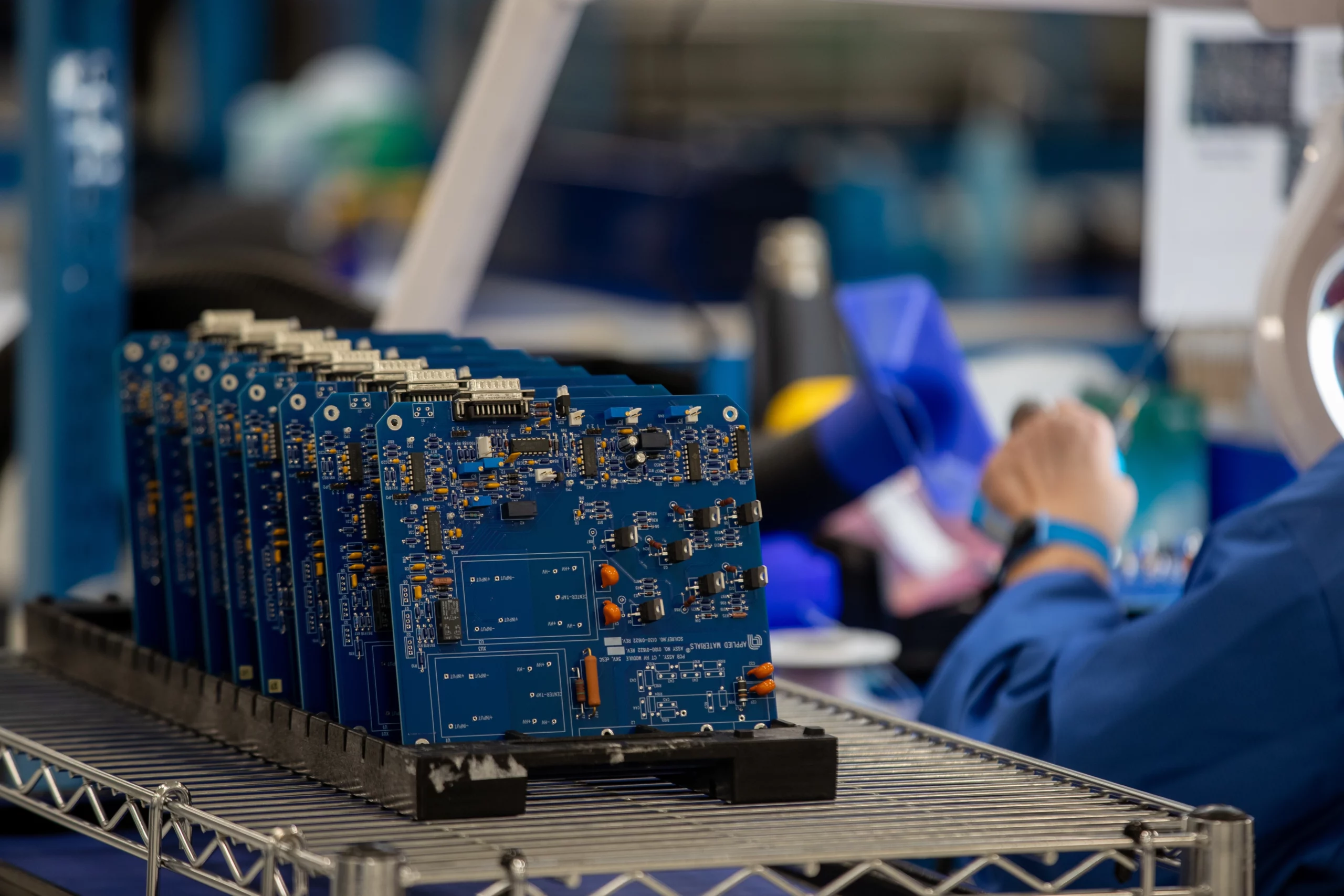

By partnering with VSE, you gain a resilient, U.S.-based manufacturing partner that safeguards your supply chain, reduces lead times, and ensures your PCB assemblies meet the highest standards of compliance, reliability, and quality.