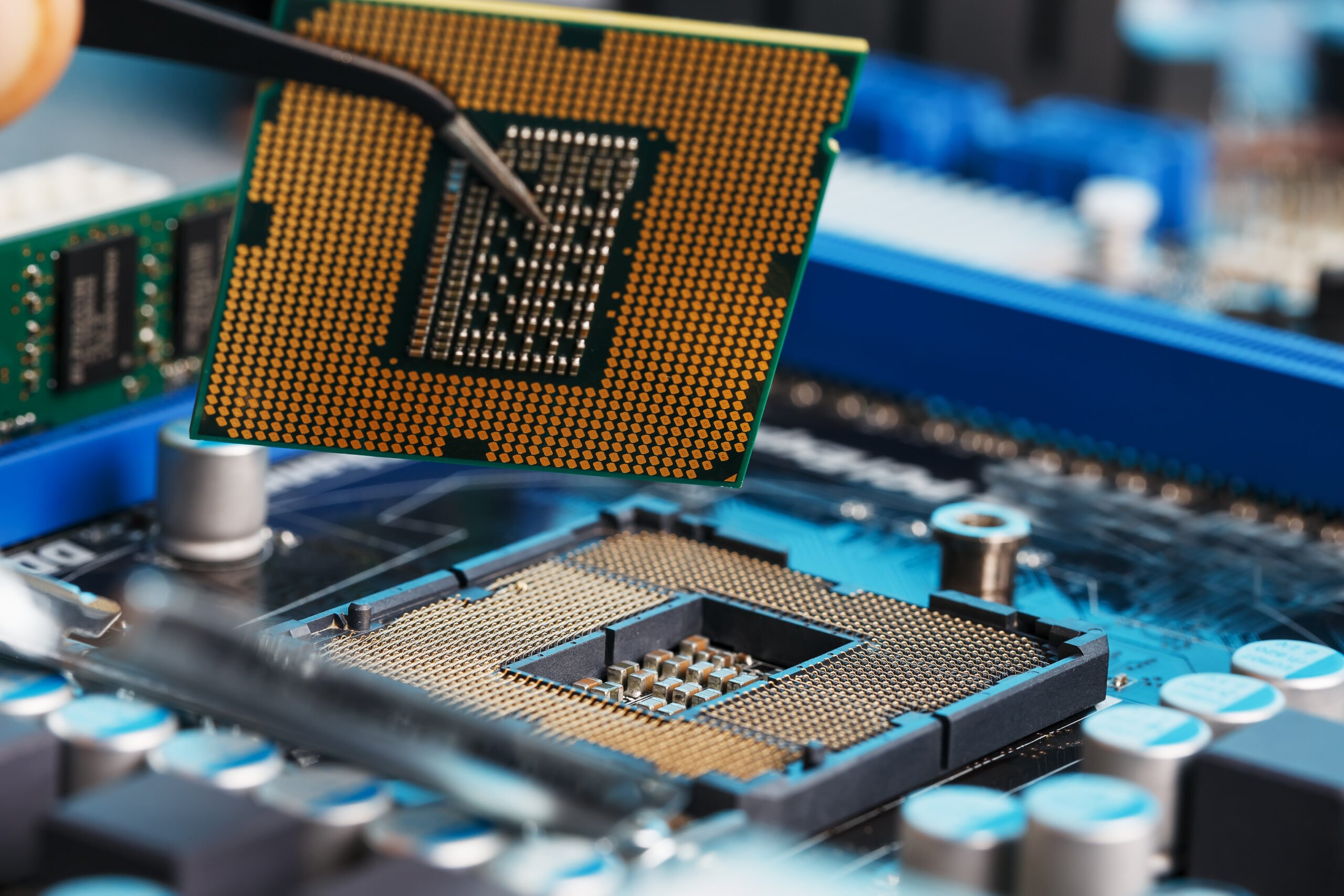

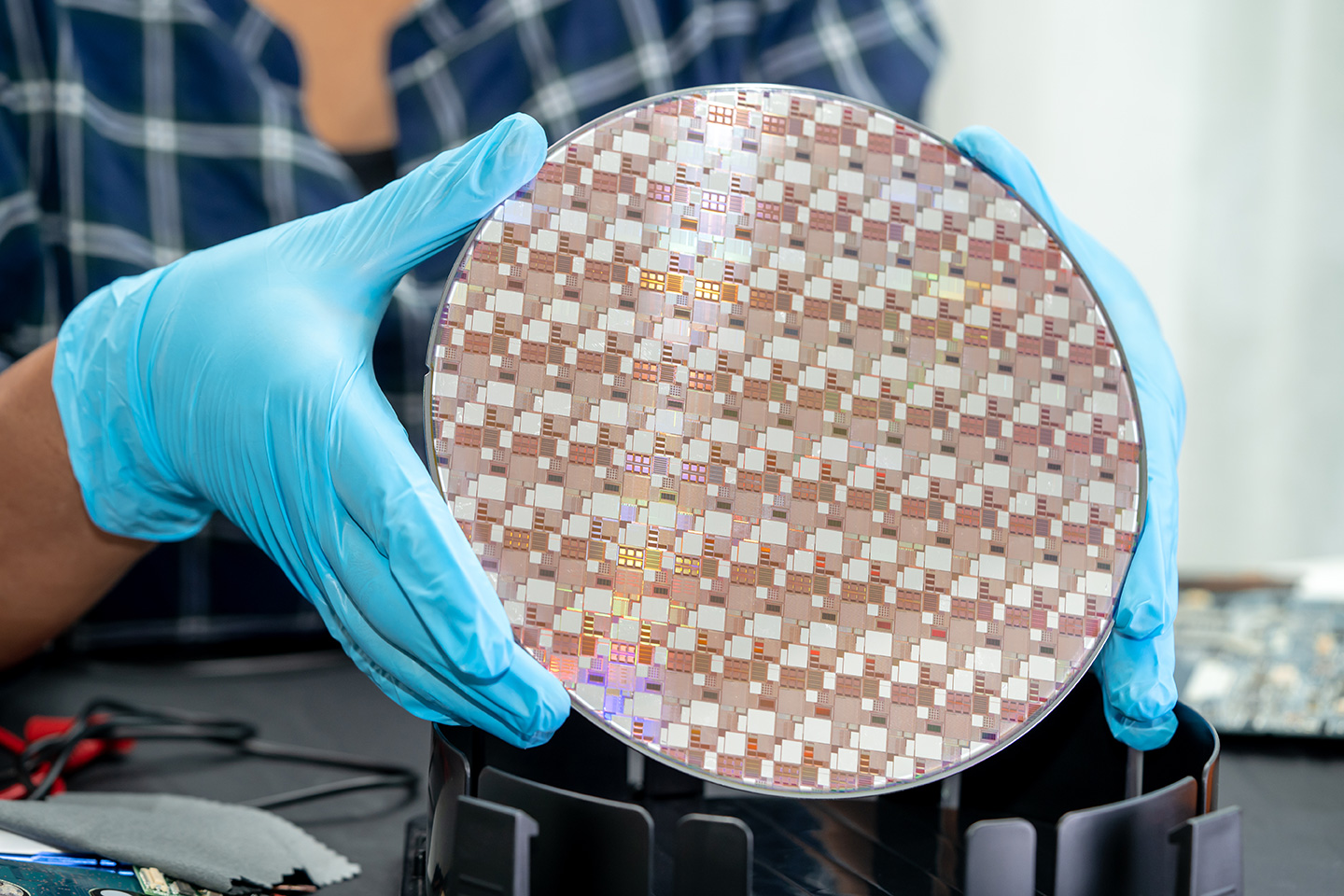

From the moment we receive supplier evaluations to meeting for an on-site audit, our commitment to statistical process control (SPC) and adherence to the strict requirements of the semiconductor industry is evident:

- At our facility, we measure the effectiveness and efficiency of every step in our manufacturing process and validate the results to ensure we’re meeting our target. This approach allows us to achieve a low cycle time without compromising quality.

- Our ISO 9001-certified quality management system ensures we maintain standardized control in the product design and manufacturing phases.

- Being an SSQA (Standardized Supplier Quality Assessment) audited and approved supplier ensures we actively pursue continuous improvement throughout our facilities.

As a result, our semiconductor equipment PCBA manufacturing processes guarantee the maintenance and improvement of quality during your initial on-site audit. It also allows us to comply with the ultimate semiconductor industry standard: copy exactly. However, our commitment to manufacturing extends beyond PCB assembly: we offer box-build capabilities and wire harness assemblies to simplify production needs further.