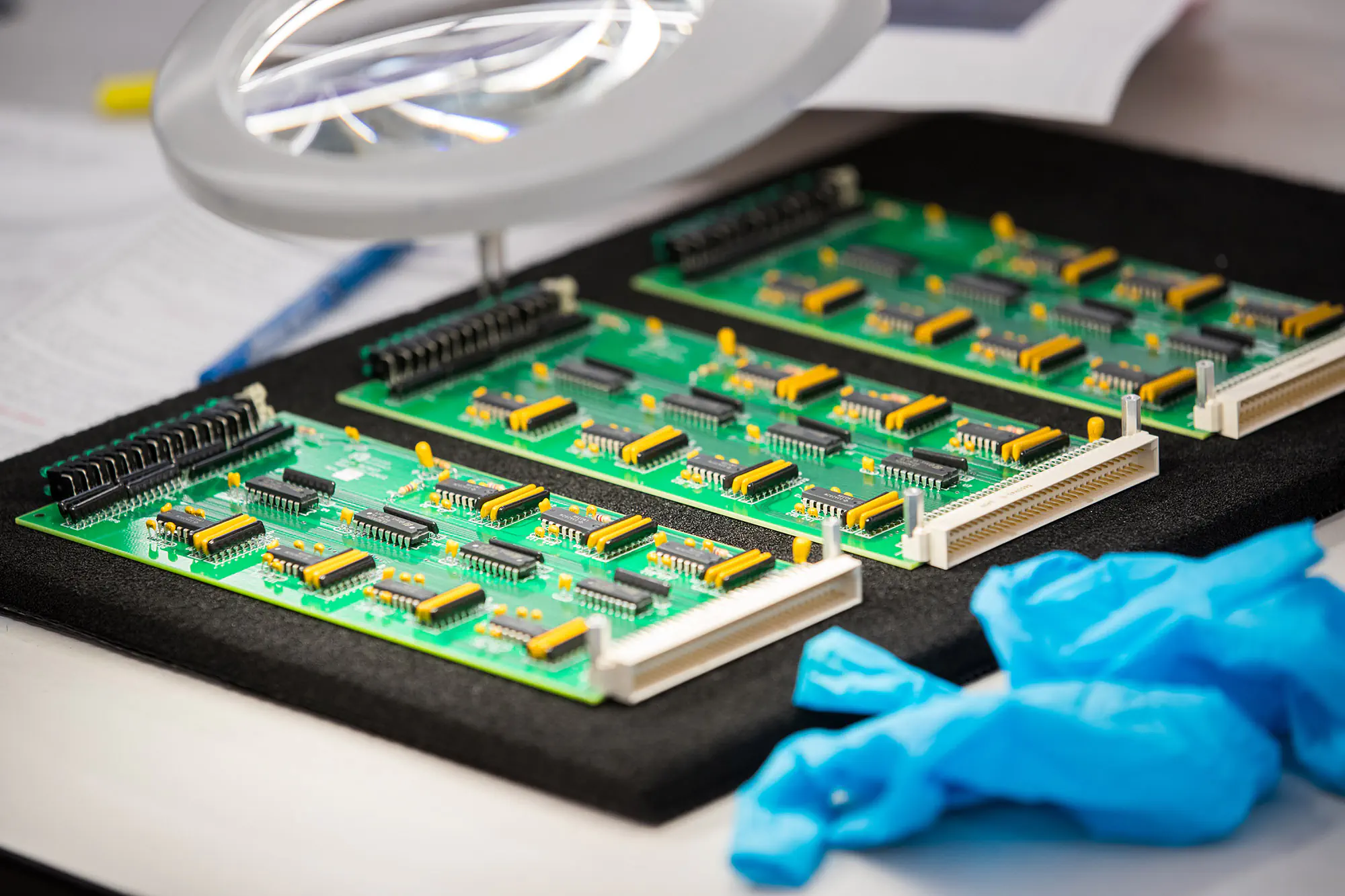

VSE’s engineers design each PCB to meet the specific performance goals of the application. Careful attention to layout, trace integrity, and thermal management helps improve signal reliability and long-term durability. Clients receive boards that perform consistently under demanding conditions, reducing maintenance and helping to prevent field failures.

VSE’s Specialized Circuit Board Design Ensures Reliable and Manufacturable Results

With over four decades of engineering experience, VSE combines advanced technical expertise with a client-focused approach to create PCB designs that meet strict quality and compliance standards. Each design is built for reliability, scalability, and speed to market—empowering clients to bring life-changing products and mission-critical innovations to reality with confidence.

VSE Expertise In Custom PCB Design Services

Our team thrives on solving complex design and performance challenges. By applying decades of cross-industry experience and adhering to ISO 9001, ISO 13485, and IPC-A-610 standards, VSE ensures every board meets the highest levels of quality and compliance.

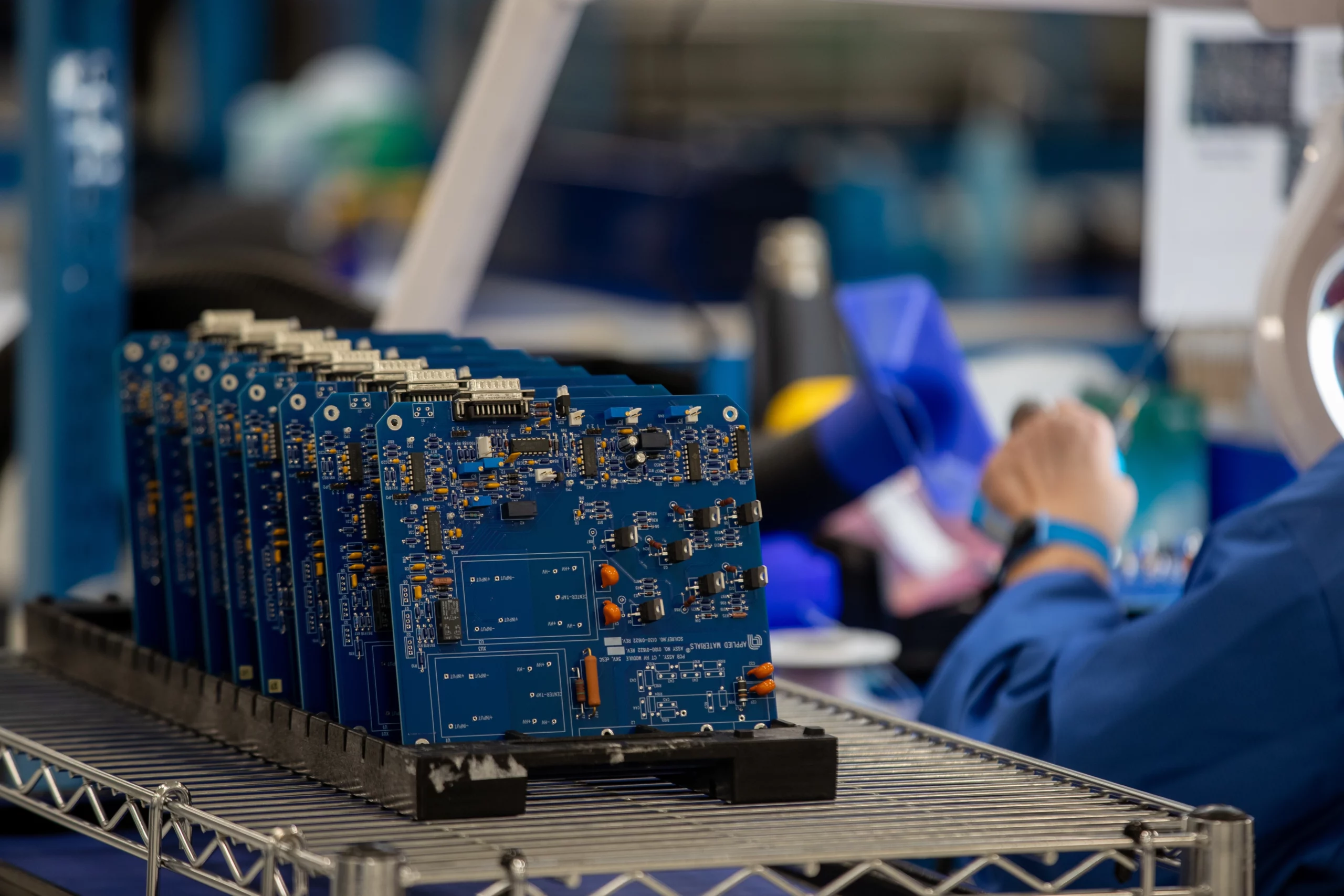

Because all engineering and manufacturing operations are U.S.-based and vertically integrated, VSE maintains complete oversight of timelines, materials, and testing. This structure supports faster project cycles, supply chain control, and the flexibility to scale as requirements evolve.

Collaboration is at the core of every engagement. VSE works as an extension of each client’s design team—offering transparent communication, agile problem-solving, and a shared commitment to bringing innovative, compliant products to market quickly and confidently.

Risks Of Inadequate Circuit Board Engineering

Common risks include:

- Limited Functionality From Standard Boards: Off-the-shelf solutions often fail to meet complex performance or integration needs.

- Manufacturing Delays Due To Layout Issues: Poor trace routing, stack-up errors, or design oversights can lead to production and testing delays.

- Supply Chain Bottlenecks: Inconsistent sourcing or reliance on obsolete components disrupts timelines and availability.

- Compliance And Certification Challenges: A lack of adherence to ISO, IPC, or industry-specific standards can delay approvals and product launches.

- Failures In High-Performance Applications: Design flaws can cause overheating, electrical noise, or early component failure in demanding environments.

- Increased Costs From Rework And Inefficiency: Design revisions and production errors add expense, waste resources, and extend delivery cycles.

How VSE Custom PCB Design Keeps Your Boards Efficient And Reliable

The following key advantages illustrate how VSE’s total-quality approach to PCB design helps keep every board efficient, compliant, and ready for real-world performance.

Through early design for manufacturability (DFM) and design for test (DFT) analysis, VSE accelerates development cycles without sacrificing quality. Quick feedback loops and collaborative in-house engineering enable faster iterations, allowing customers to validate and refine designs more quickly.

VSE bridges the gap between prototype and full production. Our vertically integrated U.S. operations enable smooth transitions, ensuring design consistency and traceability at every stage. Clients avoid the costly redesigns and communication breakdowns common with offshore or fragmented supply chains.

VSE’s secure sourcing partnerships and proactive component lifecycle management keep materials available and authentic. By sourcing directly from original equipment manufacturers (OEMs) and trusted distributors, we protect clients from shortages, obsolescence, and counterfeit risks.

Every design is backed by rigorous quality management and compliance systems. VSE operates under ISO 9001, ISO 13485, and IPC-A-610 standards, ensuring that each board meets or exceeds industry expectations for performance, safety, and reliability.

Industries We Serve With Precision

Across all sectors, VSE’s vertically integrated U.S.-based operations ensure compliance, quality, and confidence—empowering clients to bring mission-critical technologies to market with precision and speed.

Step-by-Step Process For High-Performance PCB Solutions

Built-In Reviews That Catch Issues Early

Secure Component Sourcing For Long-Term Production

Specialized Techniques For High-Density And Complex Boards

Accelerate Your PCB Projects With VSE’s Engineering Expertise

For more than 40 years, VSE has helped innovators transform complex concepts into reliable, manufacturable electronic systems. Our team combines deep engineering experience with a hands-on, partnership-driven approach that keeps projects moving efficiently from design through production.

Every board is engineered for performance, precision, and scalability. VSE’s collaborative process emphasizes early problem-solving, transparent communication, and strict compliance with ISO 9001, ISO 13485, and IPC-A-610 standards. This foundation ensures faster development cycles, fewer production risks, and consistently high-quality results.

Whether you’re developing next-generation medical devices, aerospace components, or advanced industrial systems, VSE delivers the expertise and agility to bring your vision to market securely, swiftly, and with total confidence.

Accelerate your PCB projects with VSE’s trusted, high-performance custom design services. Contact our experts today.