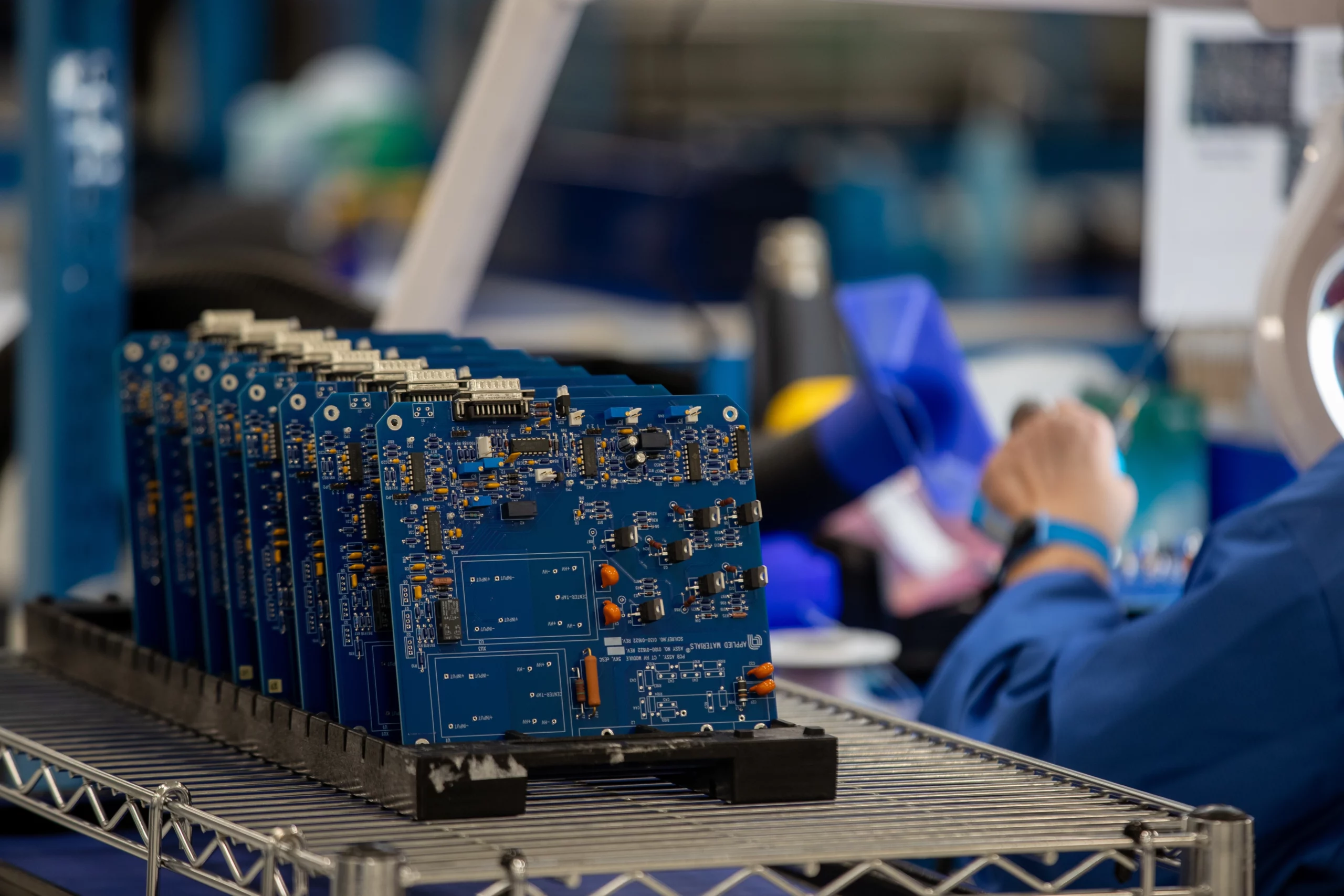

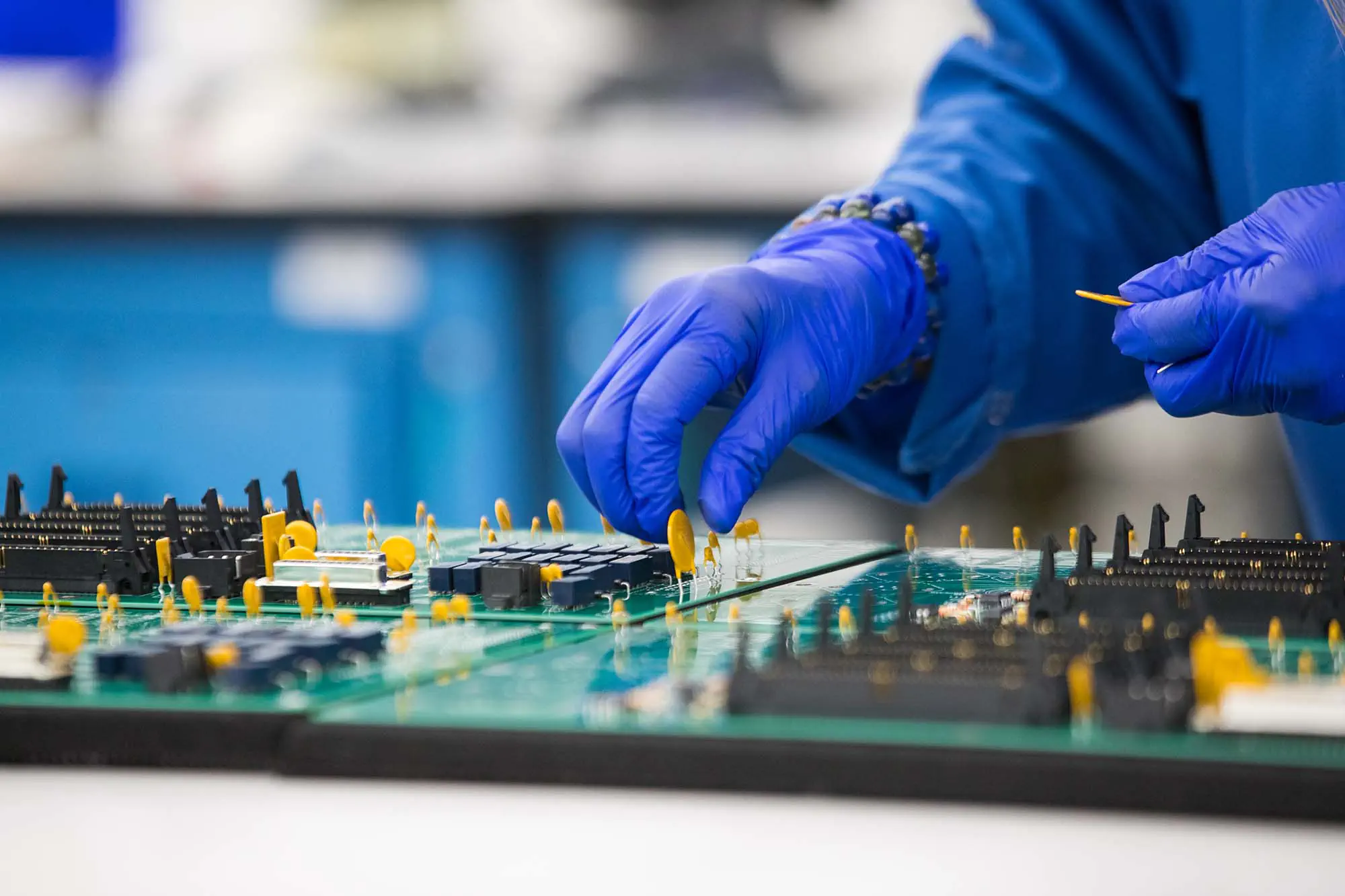

Speed and precision define every stage of production at VSE. As a trusted U.S.-based electronics manufacturing partner, we deliver rapid turnaround times without ever compromising on total quality or compliance. Our comprehensive PCB testing services ensure that every board leaving our facilities performs flawlessly—meeting the highest standards of reliability, compliance, and functionality.

From prototype validation to full-scale production, VSE’s end-to-end testing and inspection protocols enable innovators to bring products to market quickly and with complete confidence. We combine decades of engineering expertise with advanced equipment, meticulous quality control, and a problem-solving mindset to bring life-changing technologies to market with speed, transparency, and care.